Product Carbon Footprint

The Product Carbon Footprint (PCF) summarizes the total greenhouse gas emissions associated with a product throughout its lifecycle, from raw material extraction to production, usage, and disposal phases.

This comprehensive measure is expressed in CO2 equivalents (CO2e), providing a clear picture of the product's environmental impact.

How Does PCF Work?

The PCF calculation process involves several steps, starting with defining the specific issues or objectives the PCF aims to address. This clarity ensures that the assessment is tailored to meet specific needs without succumbing to greenwashing. The PCF system boundary, whether cradle-to-grave or cradle-to-gate, determines the scope of the lifecycle stages included in the analysis.

- Defining the Issue

This initial step involves identifying the purpose of calculating the PCF, ranging from understanding the overall carbon footprint of the product to comparing it with alternatives or identifying hotspots in the supply chain. - Setting the System Boundary

A key decision is whether the PCF will cover the entire lifecycle of the product (cradle-to-grave) or only up to the point it leaves the factory (cradle-to-gate). This choice affects which emissions are included in the calculation. - Data Collection

Gathering information about the production process and emissions data is crucial for PCF calculation. These data can be primary (directly controlled and known within the company) or secondary (such as average emission factors or modeling information). - Emission Calculation

The PCF is calculated by multiplying activity data by the relevant emission factors for each stage within the system boundaries. This inventory forms the basis for identifying strategies to reduce emissions and improve sustainability.

Importance of PCF

PCFs are critical for reporting emissions, identifying carbon hotspots in a product's lifecycle, and implementing decarbonization strategies. They enable manufacturers and traders to make informed decisions aligned with global climate goals and offer pathways to reduce emissions in high-impact areas.

Understanding and accurately calculating a product's PCF is increasingly vital in today’s environmentally conscious market. It allows companies to provide transparent information to customers, meet regulatory requirements, and actively participate in the transition to a net-zero carbon economy. By following standardized methodologies, such as those outlined in ISO 14040, ISO 14044, and the Greenhouse Gas Protocol, companies can ensure their PCFs are robust, comparable, and useful for driving environmental improvements.

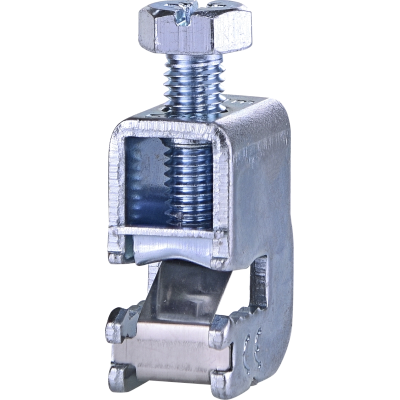

In March 2023, ETI conducted a partial PCF study for the production phase of a medium/high-voltage fuse link produced by ETI Elektroelement, d.o.o., with a rated voltage of 24kV and a rated current of 63A. The fuse link, named VVC3 (see Figure 1), is packaged in a primary package.

Medium/high-voltage fuse links are designed to protect equipment in switchgear and other devices (transformers, capacitors, motors) from thermal and dynamic effects of short circuits and overcurrent in electrical circuits. They comply with the international standard IEC 60282-1:2020. Most European electricity distribution companies use VVC3 fuse links. One of the customers for VVC3 fuse links is the Italian electricity distributor ENEL, which has internal regulations for carbon footprint calculations. As the manufacturer, ETI was required to provide the carbon footprint of the fuse link in accordance with ENEL's requirements.

Figure 1: fuse link VVC3